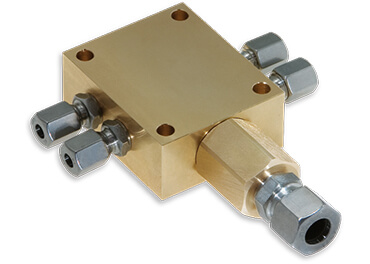

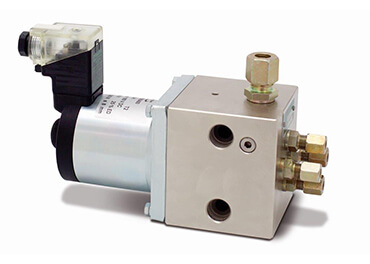

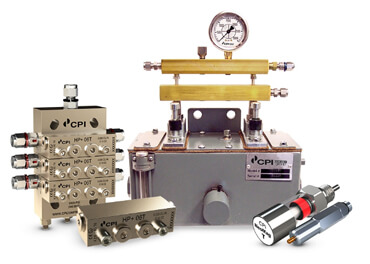

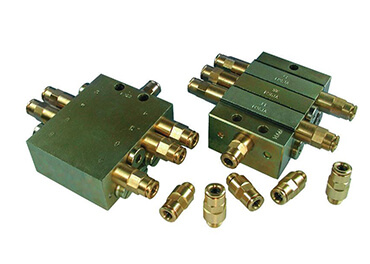

Part of centralized lubrication systems

The use of centralized lubrication systems for supplying either grease or circulating oil to components requiring lubrication is increasing dramatically. These types of systems are now used on mobile and stationary industrial equipment, on process and production line equipment, and on machine tools. A basic centralized lubrication system consists of a reservoir (to hold the oil or grease), a pump (to provide flow to the system), a control valve (to direct lubricant through various lines), a metering valve or valves (to measure and direct the necessary lubricant to the lubricated components), and a relief valve or line (to allow excess lubricant to return to the supply reservoir). There are many advantages in using centralized lubrication systems like improved machine reliability, reduced labor cost for lubricant application, reduced machinery downtime for lubricant application, more efficient use of lubricants, reduced cost of lubricants due to efficient use, improved overall lubrication of machinery, reduced lubricant waste through controlled consumption and potentially cleaner plant facilities and machinery due to reduced spills.

Part of centralized lubrication systems

- Volumetric thin oil distributer

- Single pressurization oil distributer

- 05 quantified pressurized oil distributer

- 07 quantified pressurized oil distributer

- Oil resistant-type dispenser assembly

- Progressive grease distributer

- Grease fitting proportion

- Pressure gauge

- High pressure flexible pipe

- push-in copper joint

- High pressure hose connector

- Adapter

- Grease coupler

- Grease nipple